The persons behind

ScanMan Express.

Michael Hall has 38 years of experience developing and manufacturing all type of products, with direct experience with every step of the process. 25 of those years were spent in Automotive OEM, and another 10 of them in low volume product design and development, and manufacturing all types of products.

Mike was born and raised in the center of the automotive engineering and manufacturing world, Southeastern Michigan. A place where the question "Where's my parts?" is the unofficial motto. A great place to gain invaluable exposure to the development and production of almost every type of material and manufacturing process.

But Mike wasn’t born in a factory. Mike grew up on a farm, a place where dedication, hard work, and trust-worthiness were not optional. Expectations, he says, instilled in him the importance of adding value to everything he works on, and to always think of the affect your efforts have on those around you.

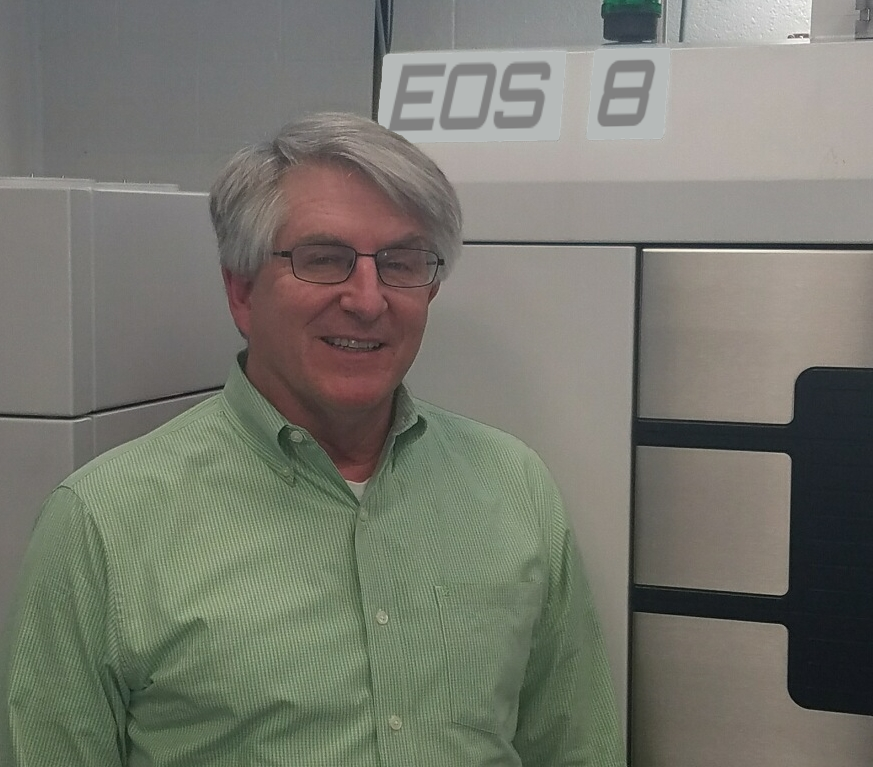

Bob Henderson’s career spans four decades of advanced manufacturing and engineering projects — from automotive to aerospace to medical industries. Educated as a mechanical/electrical engineer, he is a contributing member of the Society of Manufacturing Engineers.

Bob saw the need for ScanMan Express — a way of offering an ala carte approach to 3D structured light scanning services. “Our breakthrough tech metrology service has provided 3D structured light scanning services to customers for nearly 10 years. Over that time, we learned a lot about solving our customer’s 3D shape problems. I saw ScanMan Express as a way open up that learning and technology to anyone who can ship us their part.”

With Scanman Express he’s committed to a simple goal: deliver a service that solves your problem using the latest scanning technology, while keeping your costs up-front and efficient.

When he’s not working on helping you weave your Digital Thread he enjoy’s family, flying a light aircraft and fixing things.

He looks forward to serving your needs.

Over the last 10 years Mike and Bob have been involved in most rapid manufacturing tools, and have become masters of applying them. They call it the digital thread.

Change is constant and thriving in their current environment requires resourceful adaptability. As Mike said, “Show me the book where I can lookup how to design, adjust or calculate what the material is going to do when cured by a laser. You just need to figure it out.” And after designing and manufacturing thousands of parts, the process of figuring it out gets a little easier.

You tend to pick up a thing or two when the list of projects includes (among other things): replicating the parts for vintage race cars, replicating trim on an old building, designing medical tools, designing pillow block castings, designing vacuum molds, modifying more impeller designs than you can shake a stick at, designing and building a golf club swing trainer, and even manufacturing a fully functioning concept car. Their unique experience and gained knowledge gives them the ability to help anyone through using these high tech tools. They speak the language from the shop floor tool maker to the board room or design studio head. From engineering, design, build and inspection they're involved in all of it.

With ScanMan Express they’ve taken their high volume production experience and discipline, combined it with their low volume prototype background, and served it up in a no-nonsense ‘get the job done’ style.

And if you ask, their customers will tell you that Bob and Mike make their jobs easier.