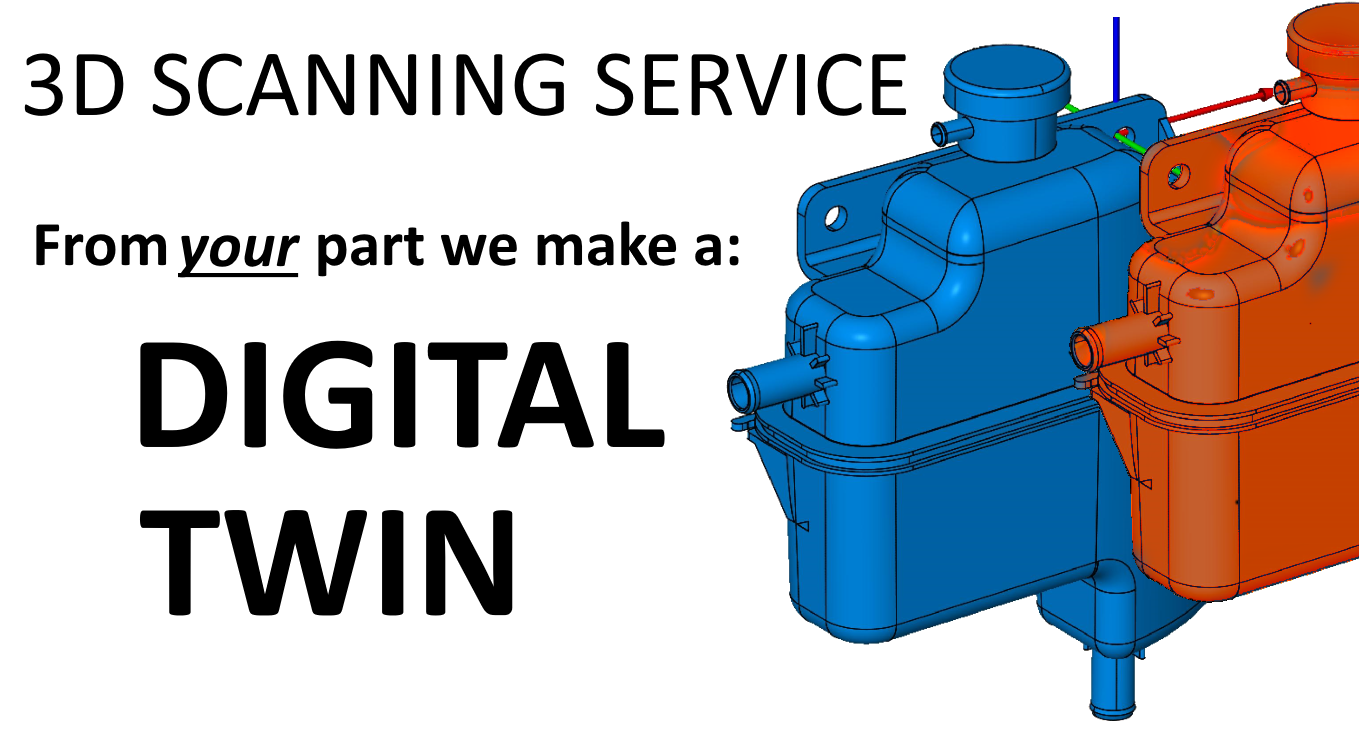

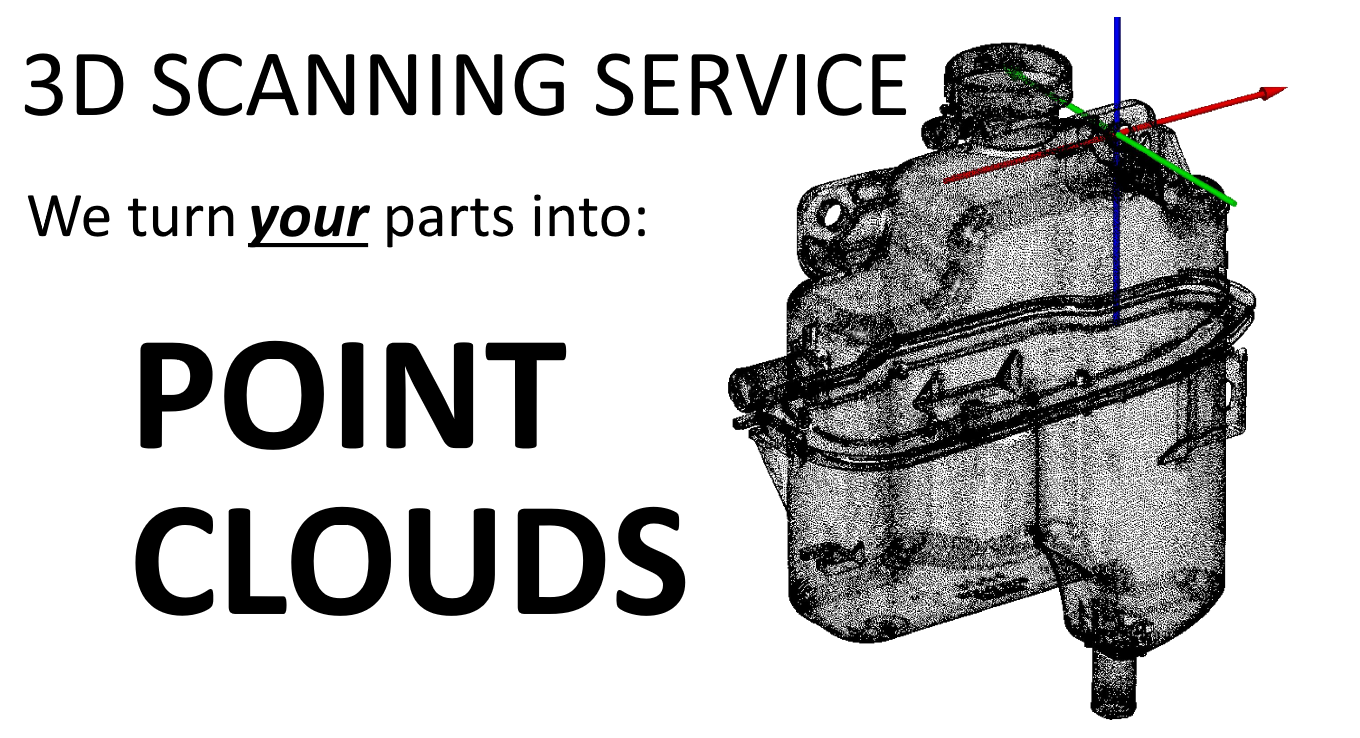

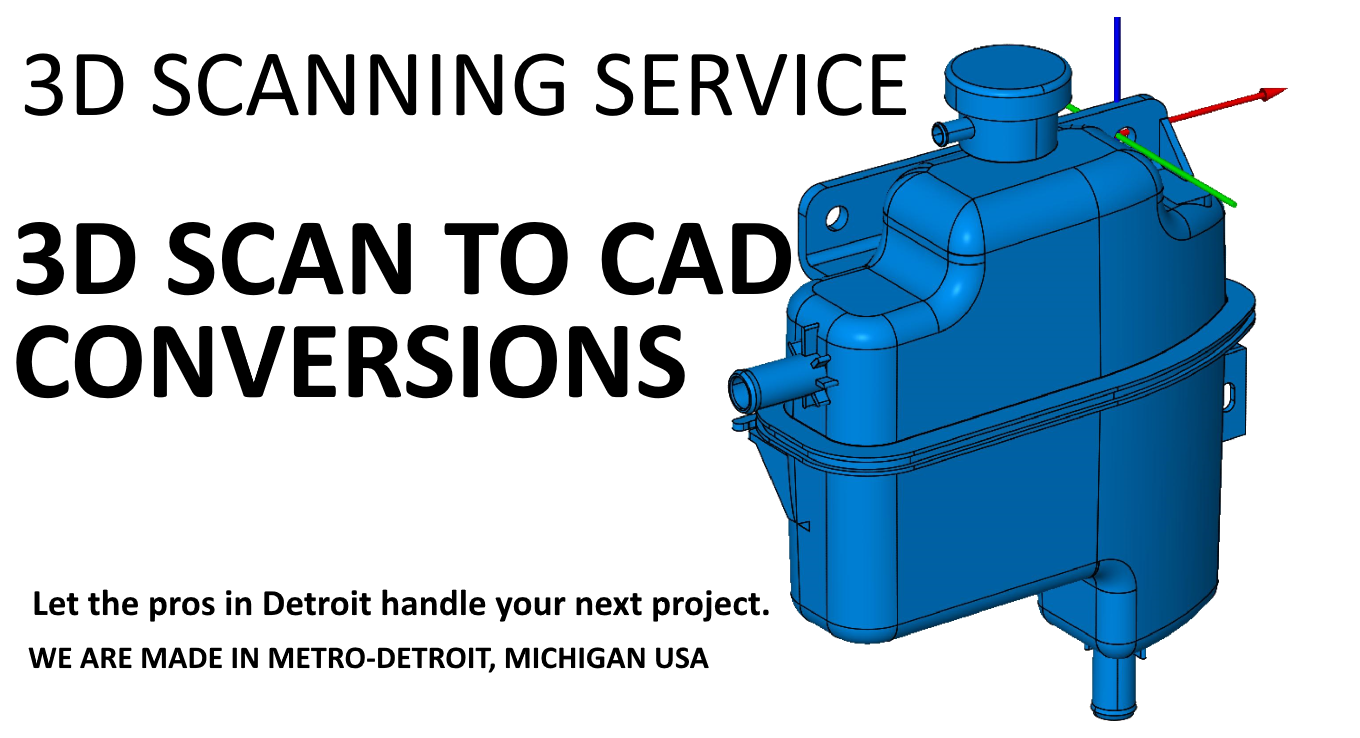

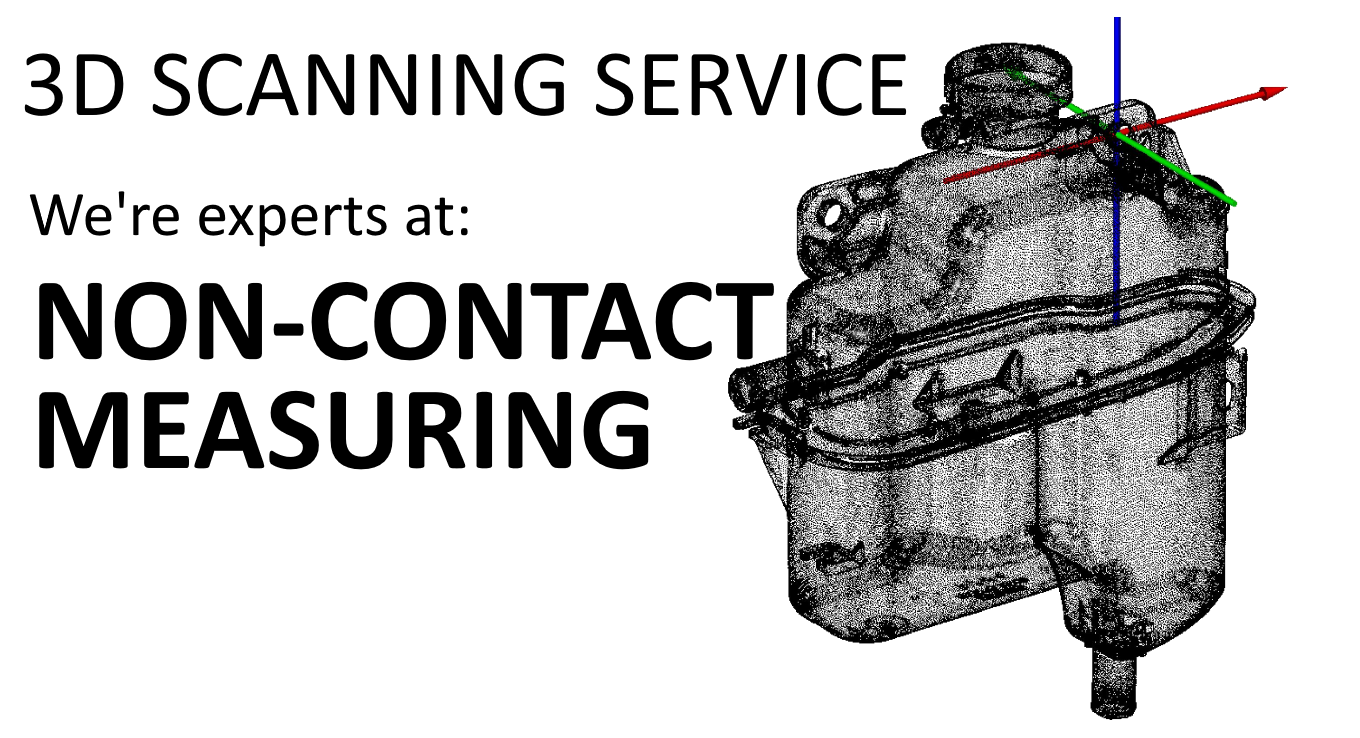

We use white light, blue light scanning technology to create digital models for use in manufacturing and other production / part-fabrication processes.

From structured light scanning we generate 3 dimensional measurement data, we interpret that data and generate 3D models, that our customers use in: 3D Printing (Rapid Prototyping, Additive Manufacturing) Part Inspections (Surface Deviation Reports, Surface Inspections) Reverse Engineering (Scan to CAD conversion, automatic and fully surfaced)

Q: HOW CAN I GET MODELS MADE OUT OF ANY OBJECT?

A: USE OUR COST CALC TO GET PRICE, SHIP PART TO US, PAY WHEN MODELS READY (OR PAY AHEAD OF TIME IF YOU WANT).

THE SCANMAN EXPRESS FROM SHIPPED PART TO 3D SCAN TO 3D MODEL PROCESS VIDEO:

AT OUR 3D SCANNING LAB WE TAKE MILLIONS OF MEASUREMENTS OF YOUR PART (IF NECESSARY). THAT DATA IS THEN USED IN:

REVERSE ENGINEERING – CAD FILE CREATION

SURFACE DEVIATION REPORTS – FIRST ARTICLE INSPECTIONS

3D PRINTING

AND MORE…

WE WORK FAST – AVERAGE TURN TIME 2-4 DAYS

Not every job is problem solving, but most are. It’s the nature of manufacturing. We operate at the speed of your project. We’re good at what we do and we will get your job done when you need it done. WE’RE ON YOUR TEAM.

COMPETITIVE PRICING

We offer cost-effective 3D Scan services. Can you find a cheaper method to scan? Perhaps. But when it comes to delivering a high level of 3D Scanning expertise at solving problems effectively and efficiently – we will not be undersold.